High Temperature Resistance Aluminum Bus Bars Busbar Bus Bar

Quick Details Place of Origin: China (Mainland) Brand Name: XINCHENG Material: 99.5% Pure Aluminum Temper: O Max. Resist

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | Round edge aluminum bus bar A 1050 for low voltage |

| Surface Treatment | Al Busbar |

| Certification | RoHS, CE, REACH, GB |

| Material | 99.5% Pure Aluminum |

| Alloy | 1050 / 1060 / 1070/1035 |

| Alloy or Not | Non-Alloy |

| Length | 100mm (Min) ~ 12000mm (Max) or Customized |

| Width | 10mm~800mm or Customer Requirement |

| Thickness | up to 400mm |

| Corner Shape | Round (Full Round)/ Square(Round Corner) |

| Edge Shape | Round Edge/ Rectangular Edge |

| Transport Package | Pallet |

| Specification | KG |

| Trademark | XINCHENG |

| Origin | China |

Product Description

Quick DetailsPlace of Origin: China (Mainland) Brand Name: XINCHENG

Material: 99.5% Pure Aluminum Temper: O

Max. Resistance: ≤0.02825

Name: ALUMINUM busbar for transformer winding Type: Plate/Belt

Application: Insulators, Electrical Winding Insulation, Winding Wire Coating Insulation, Electrical Base, Shell, Industrial Transformer, Transformer

Alloy: 1050 / 1060 / 1070/1035 Alloy or Not: Non-alloy

Length: 100mm (Min) ~ 12000mm (Max) or Customized

Width: 10mm~800mm or Customer Requirement Thickness: up to 400mm

Corner Shape: Round (Full Round)/ Square(Round Corner)

Edge shape: Round edge/ Rectangular edge

Density: 2.703 kg/dm3 ( 20ºC) Certificate: TUV, ISO, SGS

Sample: available for free Standard: ASTM AISI JIS DIN GB

Technique: Hot rolled, cold rolled, forging, casting, etc. OEM:OK

Surface Treatment: mill finished/Coated/static spray/protective film or customized

Aluminum Flat Bus Bar (1050/1060/1070/1350) Description:

The most common form of bus conductor is bar stock of rectangular cross section. This shape is inherently easy to fabricate, store, handle and erect. A relatively large surface area can be provided for the dissipation of heat by the use of multiple-bar buses. Joints and taps are readily made by either bolting or welding. Off-sets and 90-degree bends are easily made. For direct current, as well as for alternating current up to certain limits, the capacity of a bus constructed of flat bar can be controlled by merely varying the size of bars or number of bars in parallel. For high-amperage alternating current, however, special arrangements of laminations are used .

Aluminum Busbar are known for their excellent electrical conductivity properties & very good bending properties. These cater to the panels, switchgear, Farthing & other electrical bus bar applications & related industries and are available in different sizes, thickness and widths as per the requirements of the clients.

1050/1060/1070/1350 aluminum busbar belongs to EC grade aluminum bus bar. Aluminum bus bars are often used as electrical conductors in power distribution systems, where heat can easily be dissipated.

Because of the low value of the metal, it can be the best economic option for the application.

Aluminum busbar are of good surface, high strength, high conductivity, Higher Conductivity for better carrying capacity, Excellent dimensional control for superior contacts, Engineered for longer life, Crack-free Bends

Aluminum 1350 is a commercial high-purity aluminum with 61 percent conductivity. The tensile strength of each 1350 temper is determined by the amount of work given the metal during fabrication. Today, most 1350 aluminum bus conductors are of -Hlli temper for extrusions, -H112 for sawed rolled plate, and -F for cast bars.Other aluminum alloys may be used for bus conductors. However, they should be used with care since conductivity and mechanical properties can be greatly affected by small amounts of alloying elements.

Pure aluminum has low strength, but has good plasticity, weldability and corrosion resistance. Used for reflectors, lighting fixtures, ornaments, chemical industrial tanks, challenging materials, etc. Aluminum busbars are often used as electrical conductors in power distribution systems, where heat can easily be dissipated. A busbar may either be supported on insulators, or else insulation may completely surround it. Busbars are protected from accidental contact either by a metal earthed enclosure or by elevation out of normal reach.

Aluminum bus bar for transformer winding is made of 1050, 1060, 1070, and 1350 aluminum alloy, noted for its electrical conductivity. Aluminum busbar is popular for high current secondary electrical applications requiring the lightness of aluminum with moderate strength. Aluminum flat bar for transformers is rectangular and round angle. Aluminum flat bar is a high strength and lightweight material for a number of commercial and engineering applications.

1050/1060/1070/1350 aluminum busbar belongs to EC grade aluminum busbar. Aluminum bus bars are often used as electrical conductors in power distribution systems, where heat can easily be dissipated. Because of the low value of the metal, it can be the best economic option for the application.

Aluminum busbar are of good surface, high stright, high conductivity.

1050 Aluminum busbar Application:

Aluminum busbars are often used as electrical conductors in power distribution systems, where heat can easily be dissipated.

A busbar may either be supported on insulators, or else insulation may completely surround it. Busbars are protected from accidental contact either by a metal earthed enclosure or by elevation out of normal reach.

Earthing busbars are typically bare and bolted directly onto any metal chassis of their enclosure.

Aluminum bus bar Corner Shape: Round(Full Round) /Square(Round Corner)

Product Features:

Good quality of raw materials;

Standard and stable chemical composition;

Classic size tolerance;

Stable and good mechanical performance.

Perfect quality inspection means and strict quality inspection.

Our service:

1: We can provide free samples for customers to try out.

2: Provide technical advice and support in use.

3: We are ready to provide customers with the entire process of production, packaging and delivery.

4: We show the entire process of production, packaging and delivery to customer.

5: We can provide OEM or ODM services to customers.

6: Provide corresponding packing services according to customers′ regional temperature.

FAQ

Q: Can you provide free samples?

A: Of course, samples are free (1-3 pcs) or 2-3 kg

Q: How to contact your company?

A: With TradeManager or Skype or Email or the other ways we have written below.

Q: Can you give us a quotation right now?

A: Please give us detailed technical data. Then we will make a design and quotation for you as soon as possible.

Q: What is the MOQ (Minimum Order Quantity)?

A: 500kgs

Q: Do you provide your products catalogue?

A: Of course, I will send it to your E-mail if it's convenient to you.

Q: Can you do customized design and size?

A: Yes, ODM &OEM are available.

Q: What are your payment terms?

A: We accept T/T, L/C, D/P , etc.

Q: What's your delivery time?

A: 7-20 working days after received the advance payment.

Q: How to ensure the quality?

A:We can supply QC(Quality Certification),such as MTC(Mill Test Certificate),SGS Certificate,UT(Ultrasound Treatment),etc.

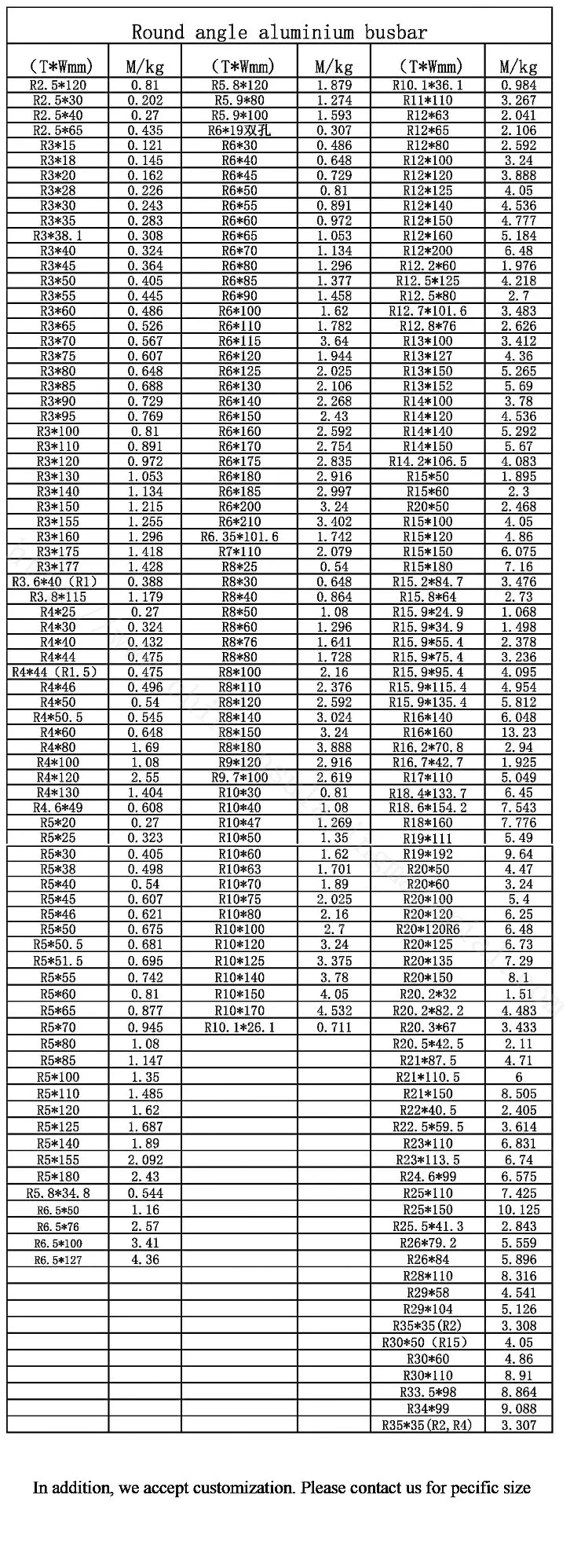

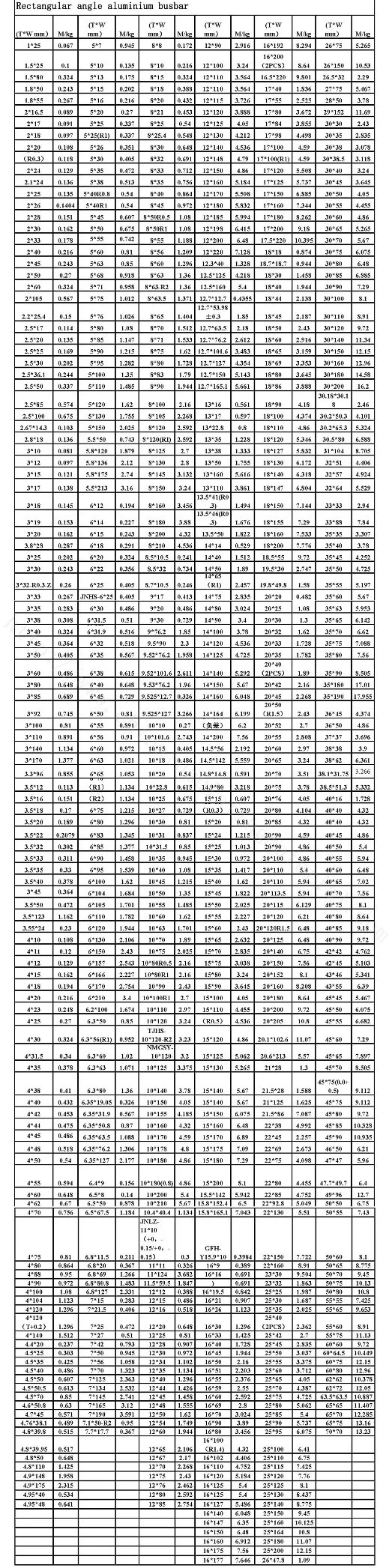

At the same time, different dimension can be customized .Welcome your inquiry.

Packaging & Shipping:

1. Inner is packed with plastic material; outer is standard iron frame or wooden cases for sea delivery;

Standard seaworthy export packing, wooden pallets with plastics protection for the sheet/plate; 2. 15-20MT can be loaded into 20'container and 21-24MT is more suitable in 40'container; 3. The other packing can be made based on the customer requirement.

4. 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High),20-25 Metric ton 40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High),20-25 Metric ton 40ft HC:12032mm(Lengh)x2352mm(Width)x2698mm(High),20-25 Metric ton

special requirements can be customized.

Delivery Detail: within 10 days after receiving deposit

Please Contact Us

Miss: lydia

Mob: 86-13752439076 Fax: 86-22-60863016